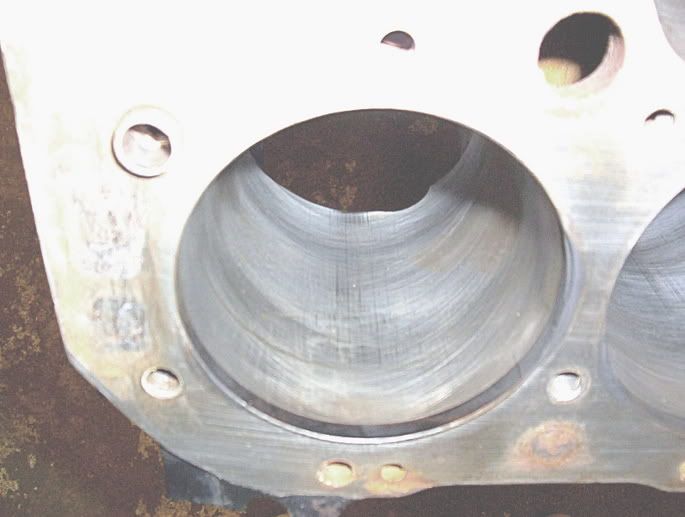

hi Gui's, i got the engine out the boat . the mechanic is allowing me to do the rebuild in his shop, with some supervision .i could work on the engine on Saturday's, something for me to do over the winter months. the engine is a 454 bb 7.4 L four bolt main oval port.

he is going to fix the leaking rings problem.

i want to start working on the heads,and i will like to put the marine items in this engine this round .

could you boys help me with the correct valve springs,valves ,VALVE GUIDES,valve seals , and what ever you think that ill need to help make my 2006 summer a trouble free year

ill take some pic of my progress at the mechanic shop

thanks..

he is going to fix the leaking rings problem.

i want to start working on the heads,and i will like to put the marine items in this engine this round .

could you boys help me with the correct valve springs,valves ,VALVE GUIDES,valve seals , and what ever you think that ill need to help make my 2006 summer a trouble free year

ill take some pic of my progress at the mechanic shop

thanks..